Documentation Home Page ◇ HYPERSIM Home Page

Pour la documentation en FRANÇAIS, utilisez l'outil de traduction de votre navigateur Chrome, Edge ou Safari. Voir un exemple.

Examples | Directional Overcurrent Protection

Location

This example model can be found in the software under the Protection > Directional_Overcurrent.ecf.

Model Description

Protection systems help in the safe operation of a power network by isolating the faulted section through breakers. The relays within that section respond in a coordinated fashion to achieve high selectivity. While the majority of the relays in the existing network are non-directional, there are certain cases where direction-based discrimination is required to determine if a relay should respond or not. The co-ordinated response of relays along with directionality ensures the safe operation of the network and minimizes service interruptions. Directional overcurrent protection relays are very useful in this regard.

Directional overcurrent protection is used to protect the system when fault currents could circulate in either direction along the network line. With the increasing penetration of Distributed Generation (DG) sources at the distribution network, it becomes even more important to implement directional protection to provide correct fault detection and ensure protection co-ordination.

This example demonstrates the operation of the Directional Overcurrent (505167) relay.

Some assumptions:

In this example, the fuses, reclosers, and sectionalisers are not implemented. The lateral lines are protected by the main-line directional overcurrent relays.

DG protection is also not discussed in this example. The focus is on feeder protection.

Network Description

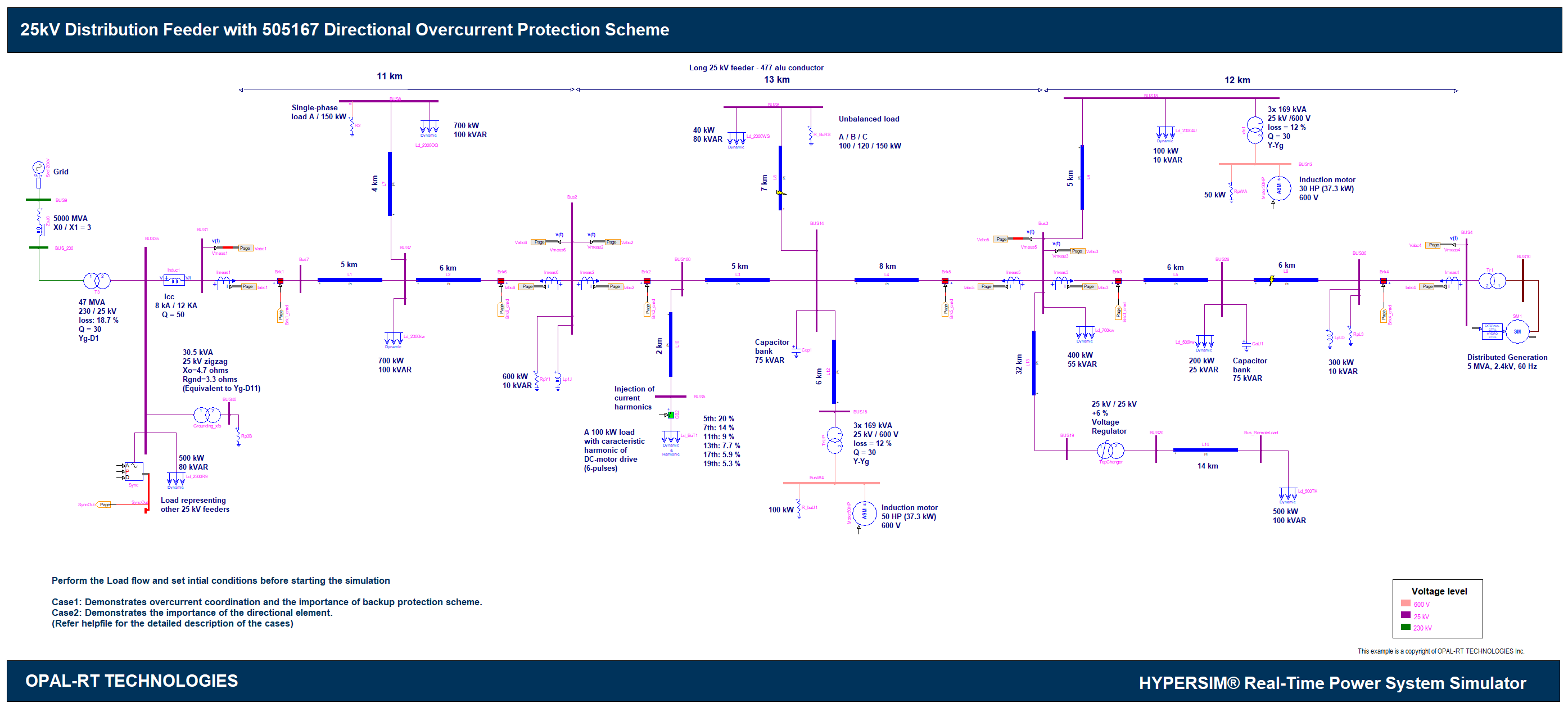

A 25 kV, 60Hz distribution feeder is used as an example for demonstrating the directional overcurrent protection relay operation. The network has two generating sources: an upstream grid modeled as a voltage source and a 5 MVA, 2.4 kV DG (modeled as a synchronous machine) connected at the other end of the feeder through a 2.4 kV / 25 kV (Delta lead- Star grounded) transformer. The DG is operating at 1.8 MW and is operating in the PV mode. The network comprises of a diversity of loads such as dynamic loads, unbalanced loads, induction motors, etc. The schematic of the system is shown in the figure above.

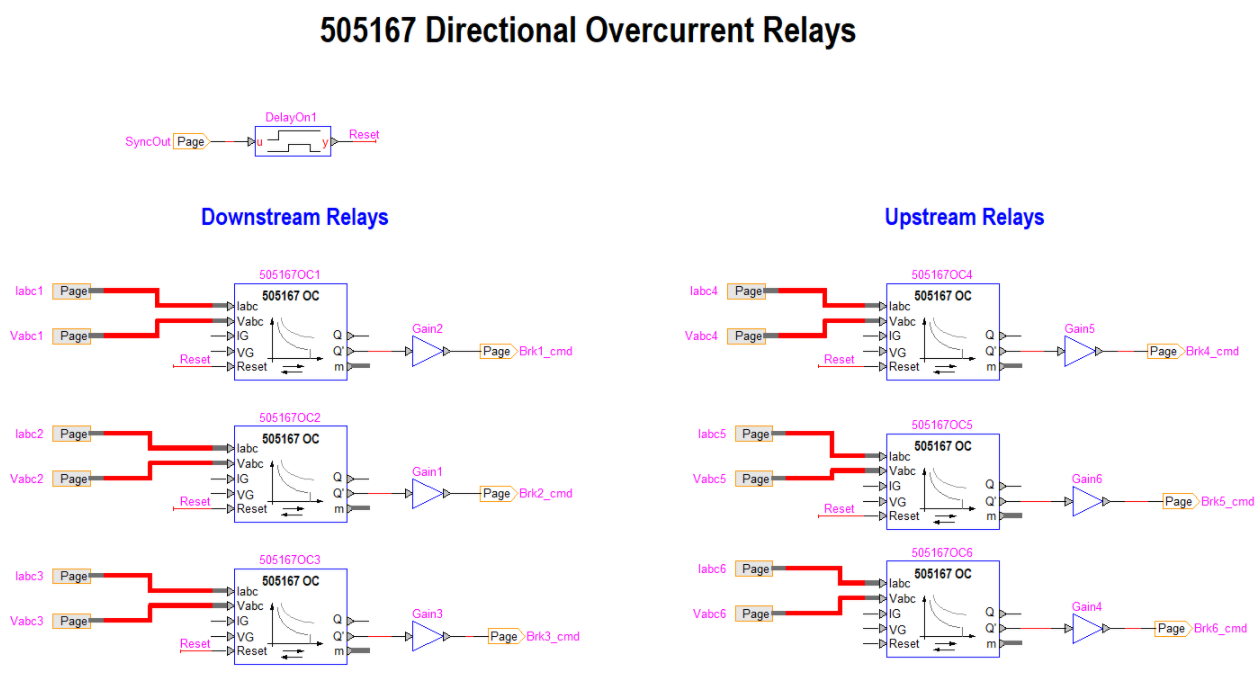

The Current Transformer (CT) and Voltage Transformer (VT) are emulated by the current and voltage measurement sensors respectively. CTs and VTs ratios are selected as 100 A / 1 A and 25 kV / 110 V respectively. The figure below shows the page 2 of the model with the sensor measurements connected to the directional overcurrent protection (505167) relays.

The complete network is divided into three sections 1,2 and 3. The directional overcurrent (505167) relays in the different sections are configured as shown in the figure and table below.

| Relay | Directional/Non-Directional | Set direction | |

|---|---|---|---|

| Downstream Relays | 1 | Non-directional | - |

| 2 | Directional | Left to Right | |

| 3 | Directional | Left to Right | |

| Upstream Relays | 4 | Non-directional | - |

| 5 | Directional | Right to Left | |

| 6 | Directional | Right to Left |

Relay Parameters

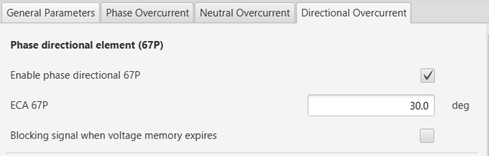

Directional Settings

In relays 2, 3, 5 and 6 the directional element (67P) is enabled by checking the 'Enable phase directional 67P'. Element Characteristic Angle (ECA) is selected as 30 deg as shown below:

Whereas in relays 1 and 4, the directional element (67P) is disabled.

Coordination of the Relays

Coordination of the Downstream Relays

The table below shows the parameters of the downstream relays, and the methodology of time dial calculation is followed:

| Relay | Base Current (A) | Base Voltage (V) | 51P Pickup current (pu) | Time Dial (s) | Curve Type |

|---|---|---|---|---|---|

| 1 | 0.59 | 65.508 | 2.0 | 0.418 | U.S. Inverse (U2) |

| 2 | 0.18 | 65.508 | 2.2 | 0.286 | U.S. Inverse (U2) |

| 3 | 0.29 | 65.508 | 1.3 | 0.04 | U.S. Inverse (U2) |

In general, the pickup current for the relay is selected such that: 1.2 Ifull_load < Ipickup < 1/3 Imin_Fault

Operating time using U.S. Inverse (U2) as per IEEE C37.112-2018 is given as:

|

|

where T.D. is the Time Dial setting

Calculation of Time Dial setting

Step 1: In this step, the Time Dial for relay 3 is set.

Choose the lowest value of Time Dial setting for relay 3 (0.04 s). No intentional time delay is provided because it does not have backup responsibility.

For close-in fault (three-phase-to-ground fault close to relay) at relay 3 ( )* at the relay terminals, the operation time of relay 3 is:

|

|

Step 2: In this step, Time Dial for relay 2 is set.

We co-ordinate relay 2 with relay 3 for close-in fault for relay 3.

For close-in fault at relay 3, the relay 2 will act as a backup protection, the time of operation of relay 2 will be:

Expected operating time for relay 2 = Operating time of relay 3+ coordination time interval (example: 0.05 s)

= 0.008 + 0.05 s

= 0.058 s

|

|

Step 3 : In a similar way relay 1 is coordinated with relay 2.

The characteristic curves of the downstream relays with the parameters from the table above are shown in the figure below:

* Fault studies were performed and the fault currents were noticed.

Coordination of the Upstream Relays

The upstream relay parameters are shown in the table below:

| Relay | Base Current (A) | Base Voltage (V) | 51P Pickup current (pu) | Time Dial (s) | Curve Type |

|---|---|---|---|---|---|

| 4 | 0.41 | 65.508 | 1.3 | 0.38 | U.S. Inverse (U2) |

| 5 | 0.09 | 65.508 | 2 | 0.305 | U.S. Inverse (U2) |

| 6 | 0.25 | 65.508 | 1.3 | 0.04 | U.S. Inverse (U2) |

Characteristic curves of the upstream relays with the parameters from the table above are shown in the figure below:

Simulation and Results

To start the simulation in a steady-state, the network must be initialized by the Load Flow.

Open Network -> Load Flow and make sure the frequency is 60 Hz.

Open Simulation Settings and enable the option "Perform load flow and set initial conditions at simulation start". Make sure the time step is set to 50 us.

Warning: When executing in real-time on Redhat targets., model doesn't work with "opicc" in Settings – Target – Compiler and Linkerworks.

Case 1: Overcurrent coordination and the role of the backup protection scheme

A three-phase-to-ground fault (ABC-G) is applied at t = 0.2 s on a 7 km lateral line connected at Bus 14 in section 2. Since the fault occurs in section 2, relays 2 and 5 should pick up and clear the fault by opening the Circuit Breaker (CB) 2 and 5 respectively.

It is demonstrated in this case that in the event of a breaker failure (example: CB 2 fails to operate), then relay 1, which is the backup protection for section 2 faults will pick up and clear the fault by opening CB 1. This demonstrates the coordination between overcurrent relays and the importance of backup protection. The test case is described in the figure below:

Steps to be followed:

Open the control panel of the line 'L8' which is a 7 km Lateral line connected at Bus 14 in section 2. Enable ‘Time programming’ in the ‘Timing’ tab.

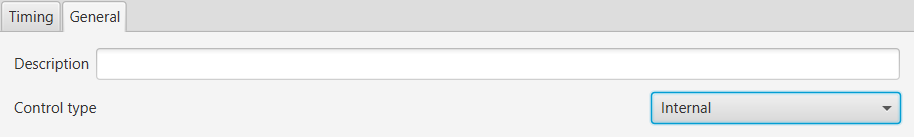

Open the control panel of Brk2, in the 'General’ tab, change the ‘Control type ’ from 'External (input pins)' to 'Internal' as follows:

This allows Brk2 to not to be controlled by relay 2 output. This is to simulate a breaker failure scenario.

Now, start the simulation and launch ScopeView, open the template: ‘Directional_Overcurrent.xml’.

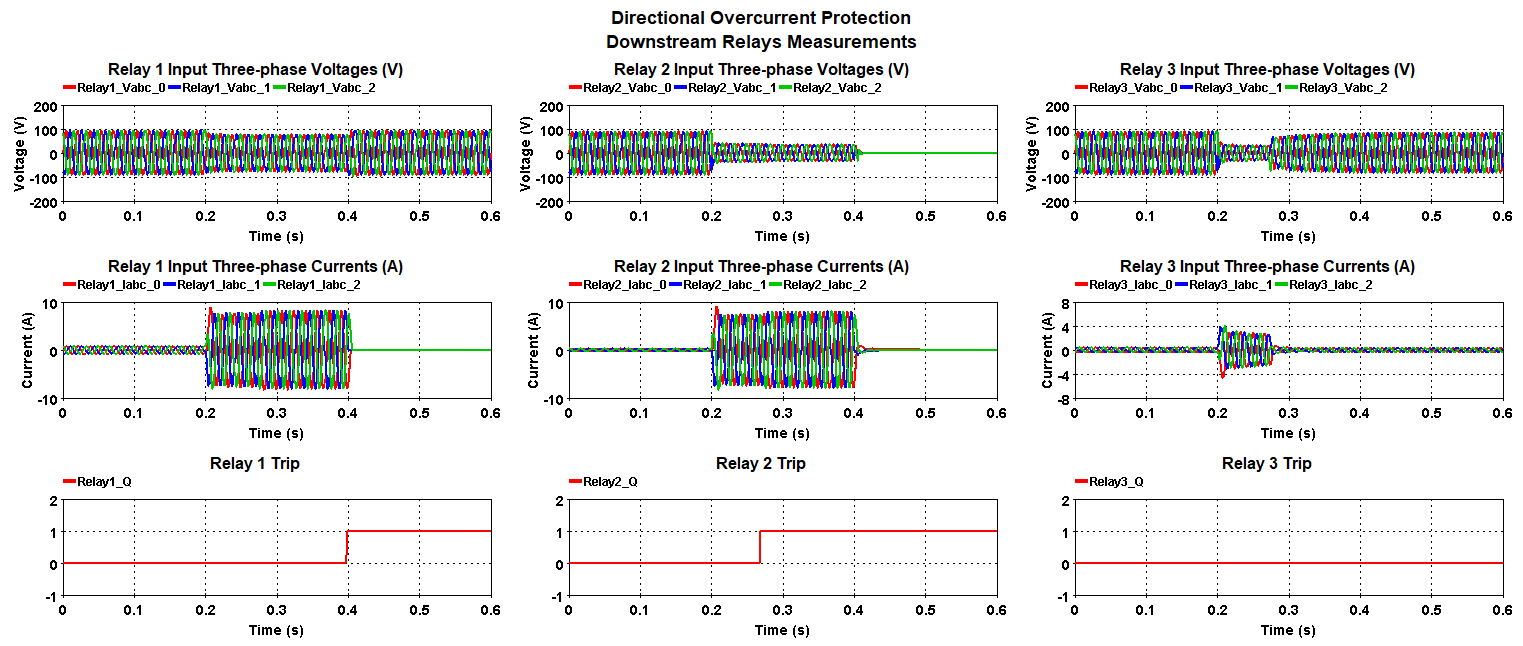

Make sure both ‘Sync’ and ‘Trig’ are checked, then start the data acquisition. The figure below shows the downstream relays voltages, currents, and the trip output.

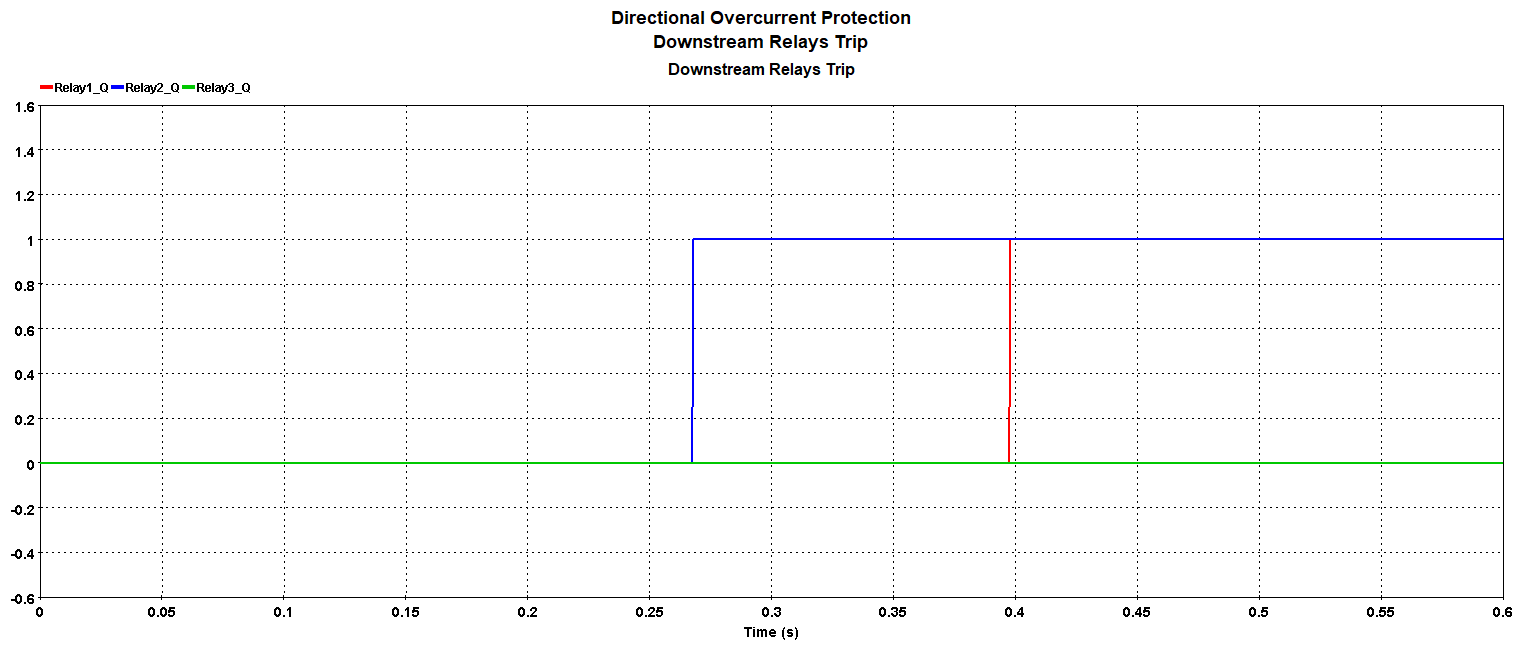

As shown in the figure below, the relay 2 picks up in 0.067 s (from the time of fault) and breaker 2 (supposed to be controlled by relay 2) fails to clear the fault. Relay 1 which is the backup protection for section 2 faults, picks up in 0.1975 s and clears the fault by opening breaker 1. This clearly demonstrates the coordination among the relays and the importance of a backup protection scheme.

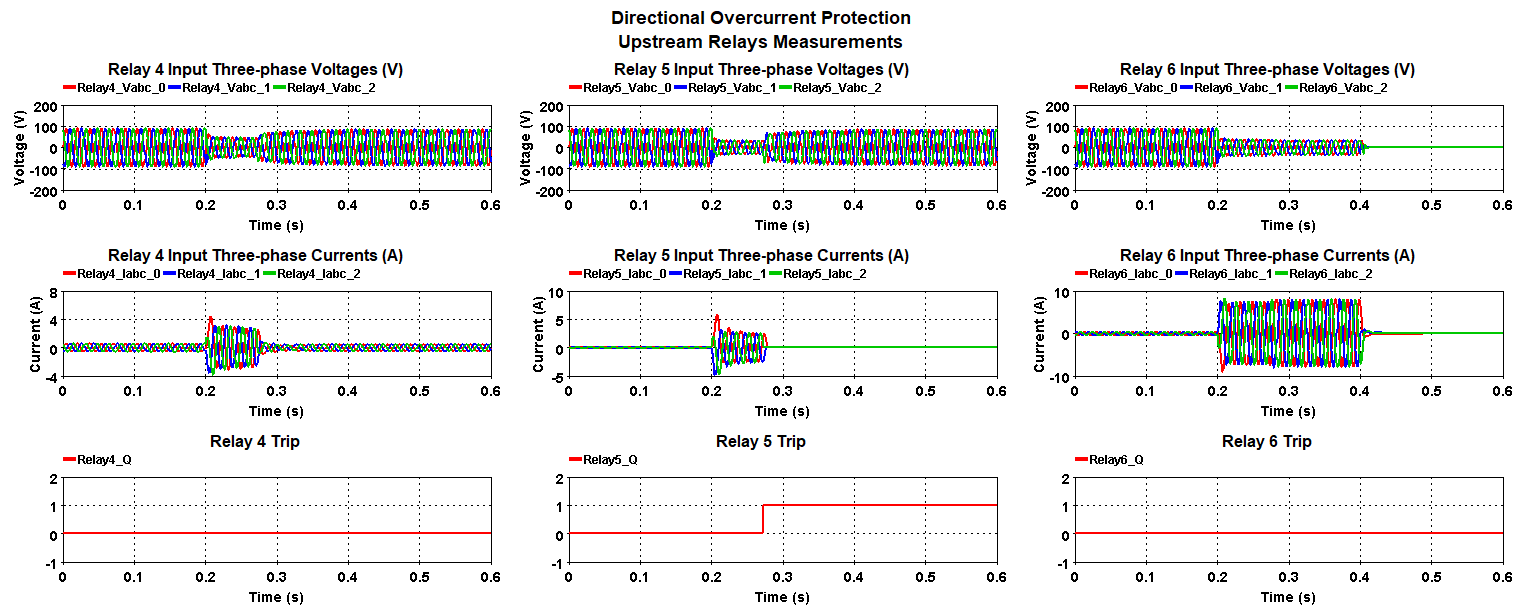

The figure below shows the upstream relays voltages, currents, and the trip output. Since the fault is in section 2 so relay 5 should pick up and clear the fault by opening CB 5.

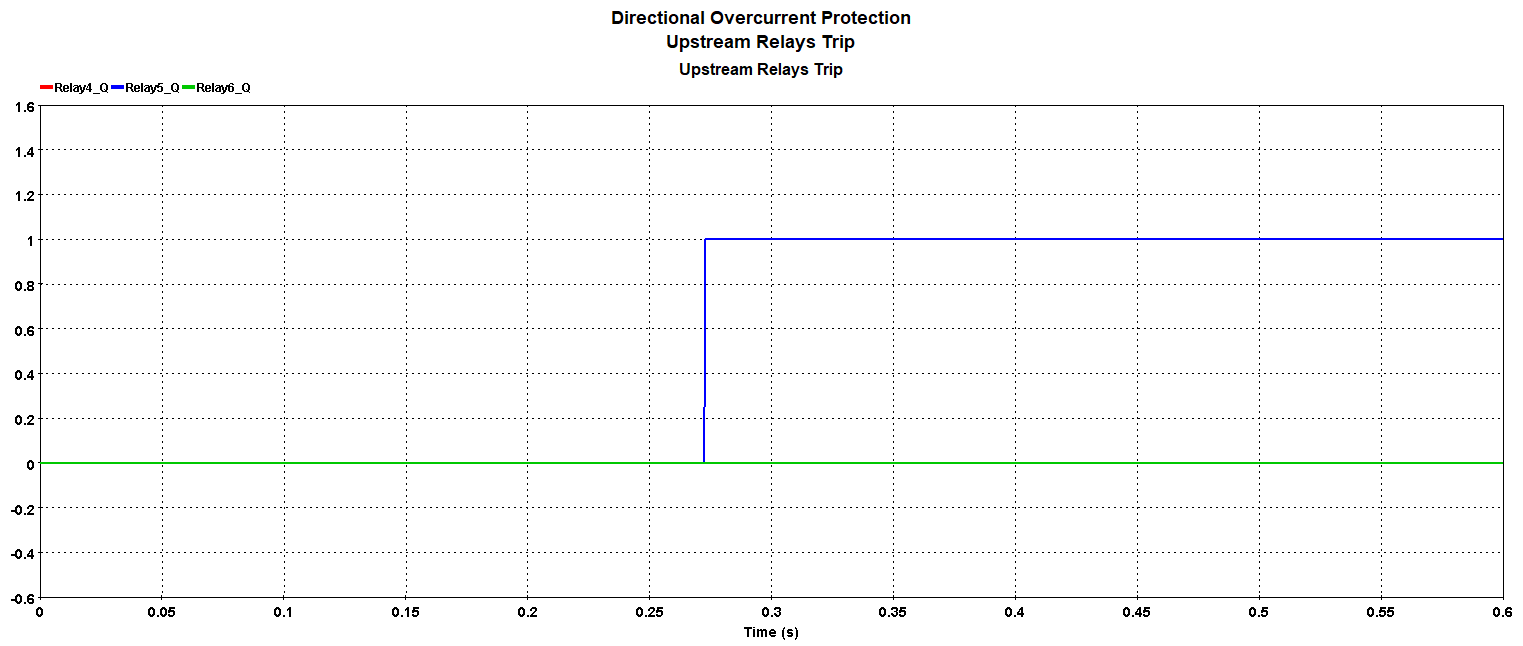

As shown in the figure below, relay 5 picks up in 0.0727 s (from the time of fault) and clears the fault by opening CB 5, as expected. Relay 4 and 6 do not operate.

Case 2: Importance of directional element in the protection scheme

A. When the directional element is enabled in the relays

A three-phase-to-ground fault (ABC-G) is applied at t = 0.2 s on a 6 km line connected between Bus 26 and 30 in section 3. Since the fault is applied in section 3, all the downstream relays (1,2 and 3) will see the fault direction in the set direction but relay 3 with the lowest Time Dial setting will pick up and clear the fault. The upstream relays 5 and 6 will see the fault direction opposite to the set direction therefore will not respond. The upstream relay 4 which is non-directional will pick up and clear the fault.

The test case is described in the figure below:

Steps to be followed:

Stop the Simulation and make sure that the 'Enable phase directional 67P' setting of the relay 2, 3, and 5 is checked.

Open the control panel of the line 'L8' which is a 7 km Lateral line connected at Bus 14 in section 2. Disable ‘Time programming’ in the ‘Timing’ tab.

Open the control panel of the line 'L6' which is a 6 km line connected between Bus 26 and 30 in section 3. Enable ‘Time programming’ in the ‘Timing’ tab.

Open the control panel of Brk2, in the ‘General’ tab, change the ‘Control type’ from 'Internal' to 'External (input pins)'.

Start the simulation and observe the results in ScopeView.

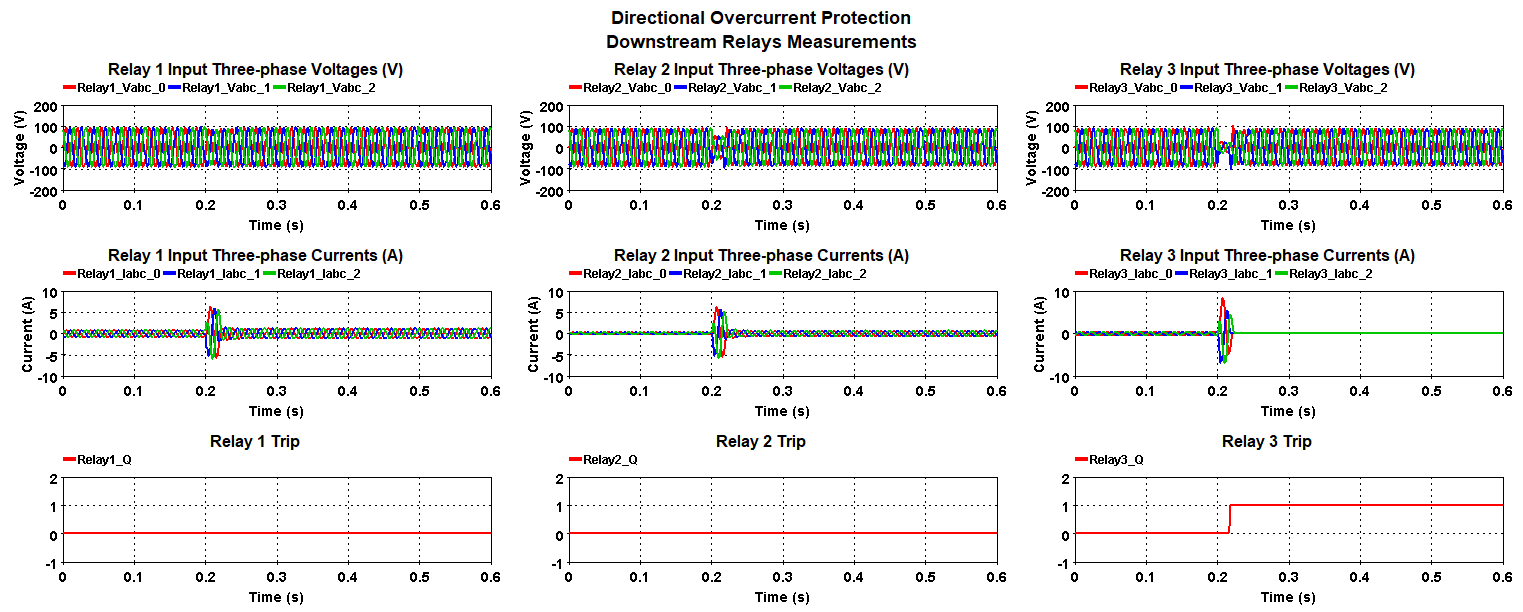

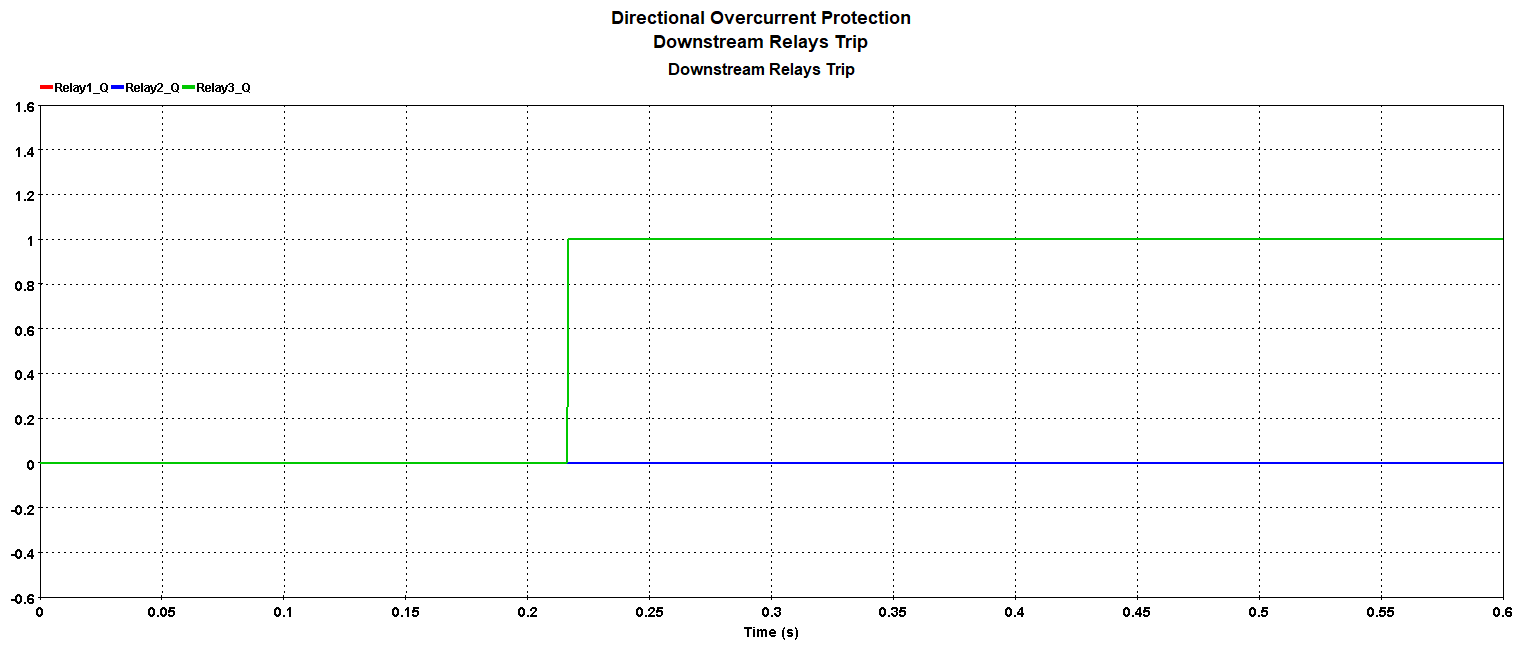

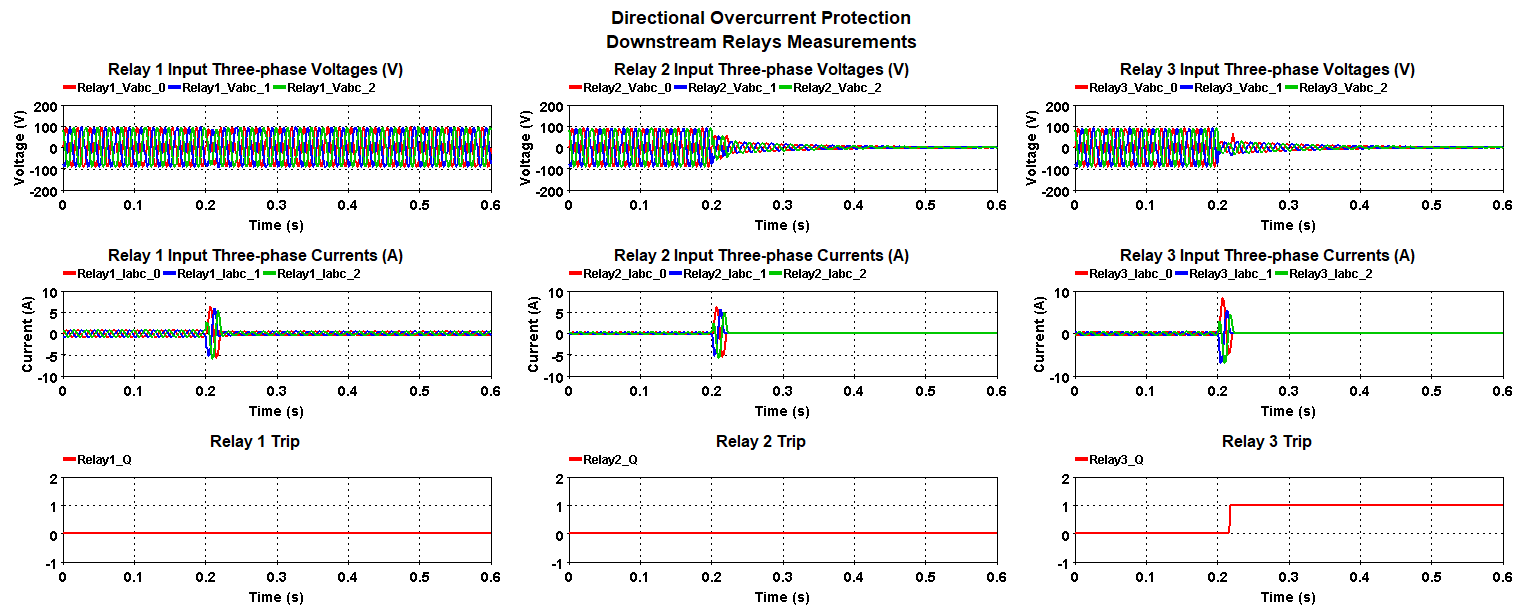

The figure below shows the downstream relays voltages, currents, and the trip output.

As the fault is in section 3, relay 3 picks up first in 0.0161 s (from the time of fault) and clears the fault by opening breaker 3 as expected.

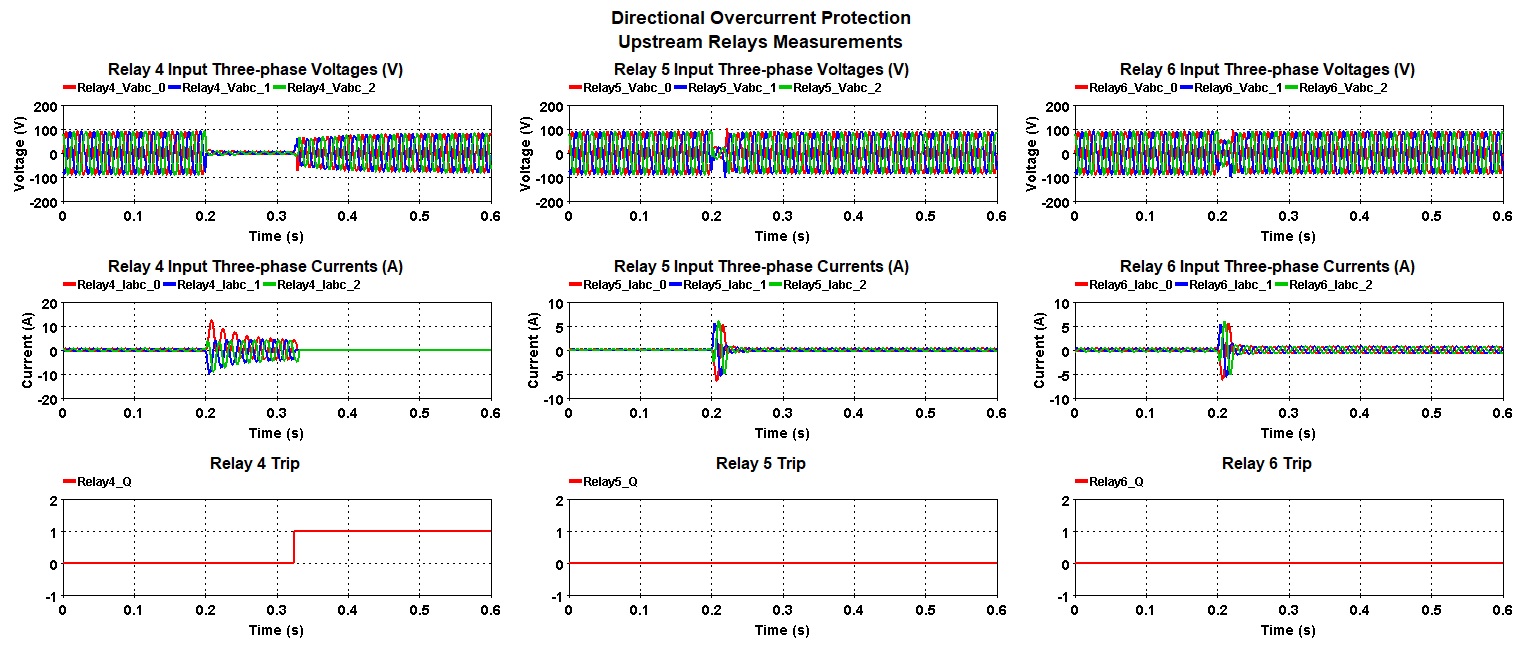

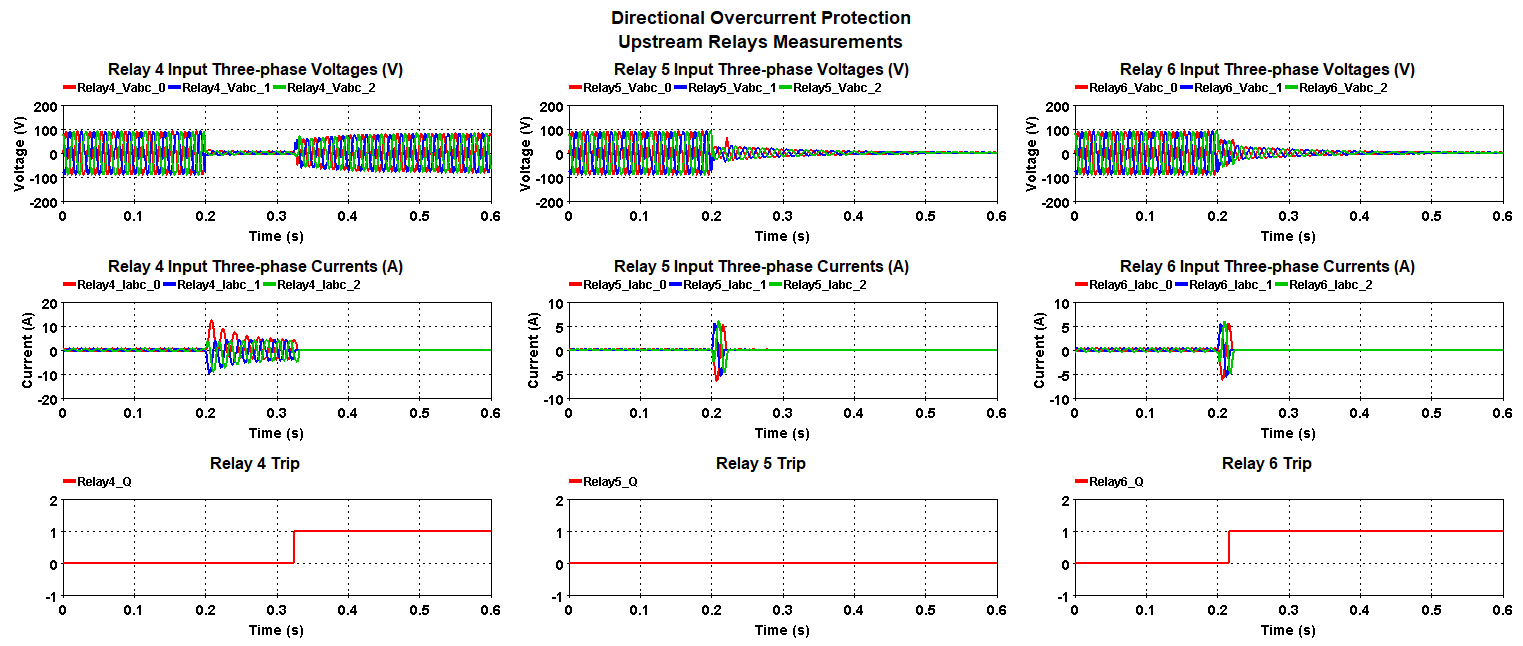

The figure below shows the upstream relays voltages, currents, and the trip output.

As the fault is in section 3, relay 4 picks up first in 0.1237 s (from the time of fault) and clears the fault by opening breaker 4 as expected.

B. When the directional element is disabled in the relays

The response of the protection system when the directional element (67P) is disabled is shown in this case. The fault conditions are similar as described in Case 2A.

Steps to be followed:

Stop the simulation and disable the directional element by unchecking the 'Enable phase directional 67P' setting of the relay 2,3,5 and 6. Start the simulation and observe the results in ScopeView.

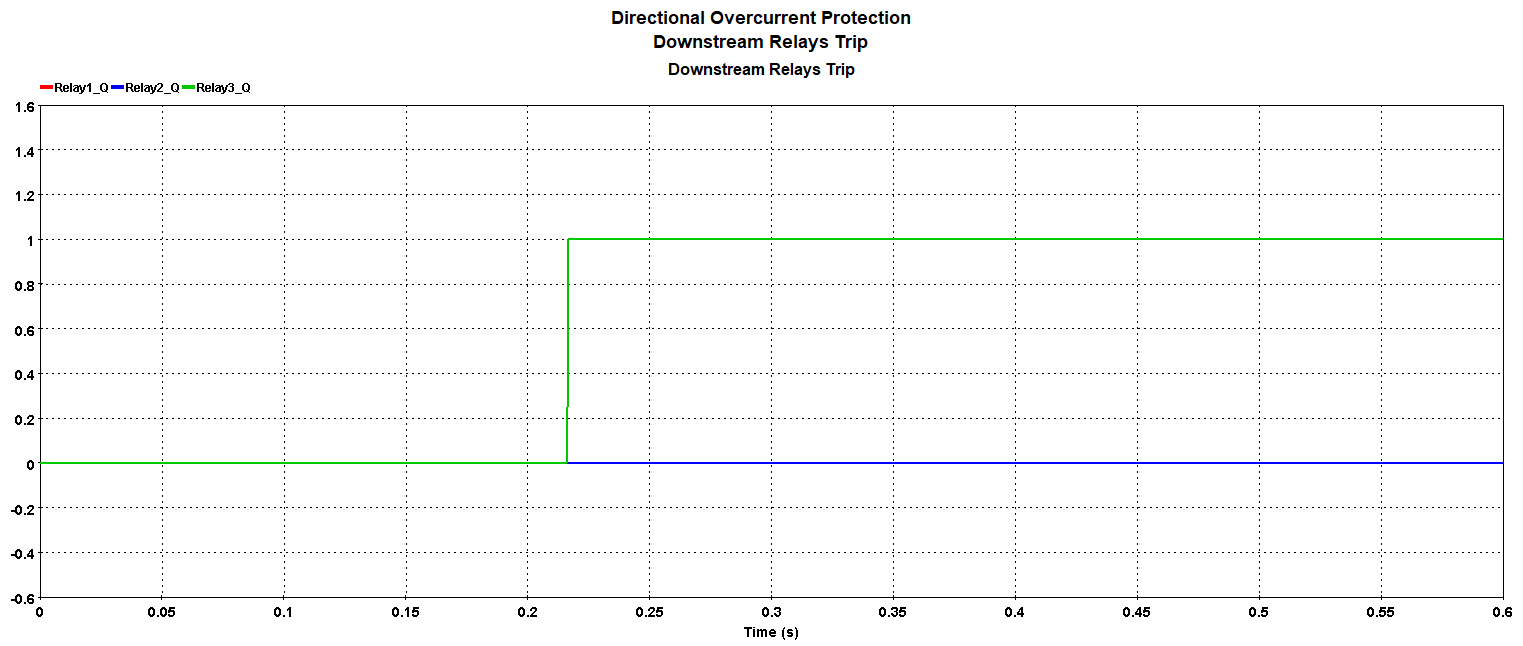

The figure below shows the downstream relays voltages, currents, and the trip outputs. As all the downstream relays observe the fault, relay 3 with the lowest Time Dial (0.04 s) setting will pick up first.

The figure below shows relay 3 picks up first in 0.0161 s (from the time of fault) and clears the fault by opening the breaker 3.

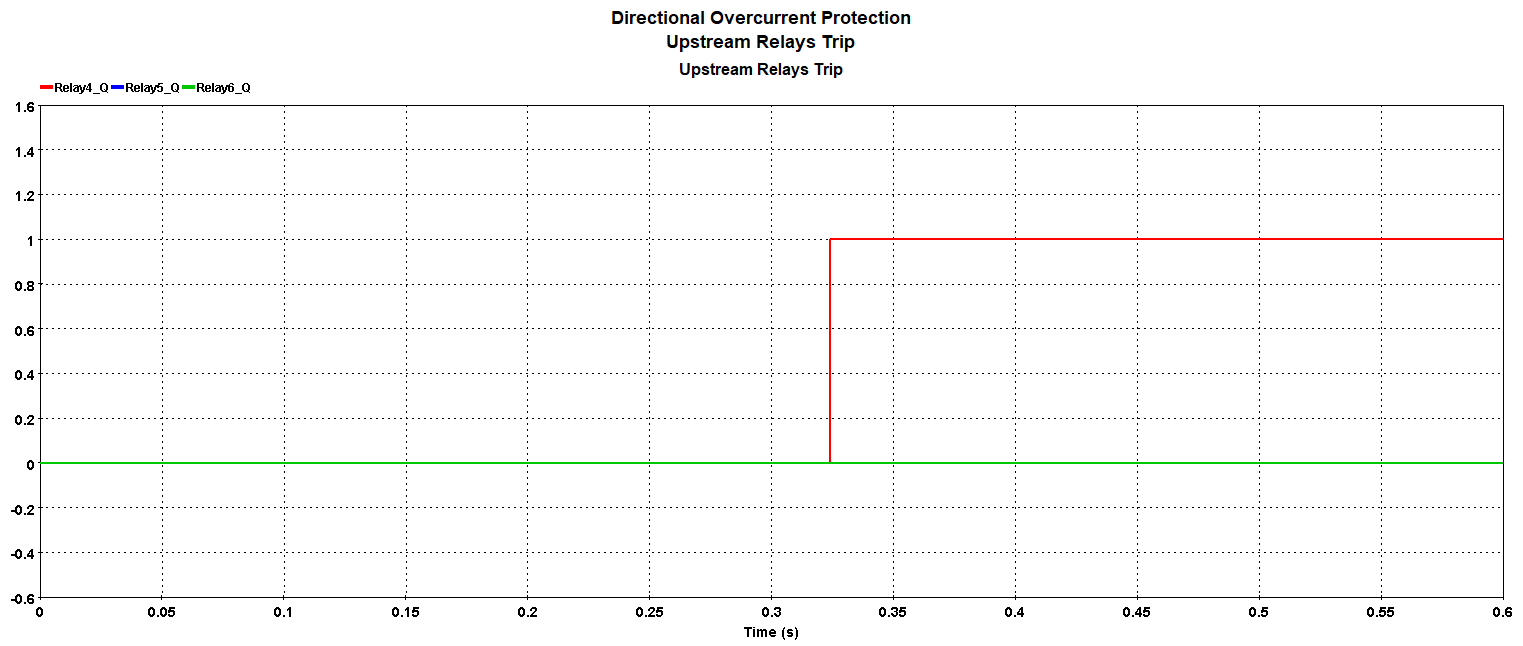

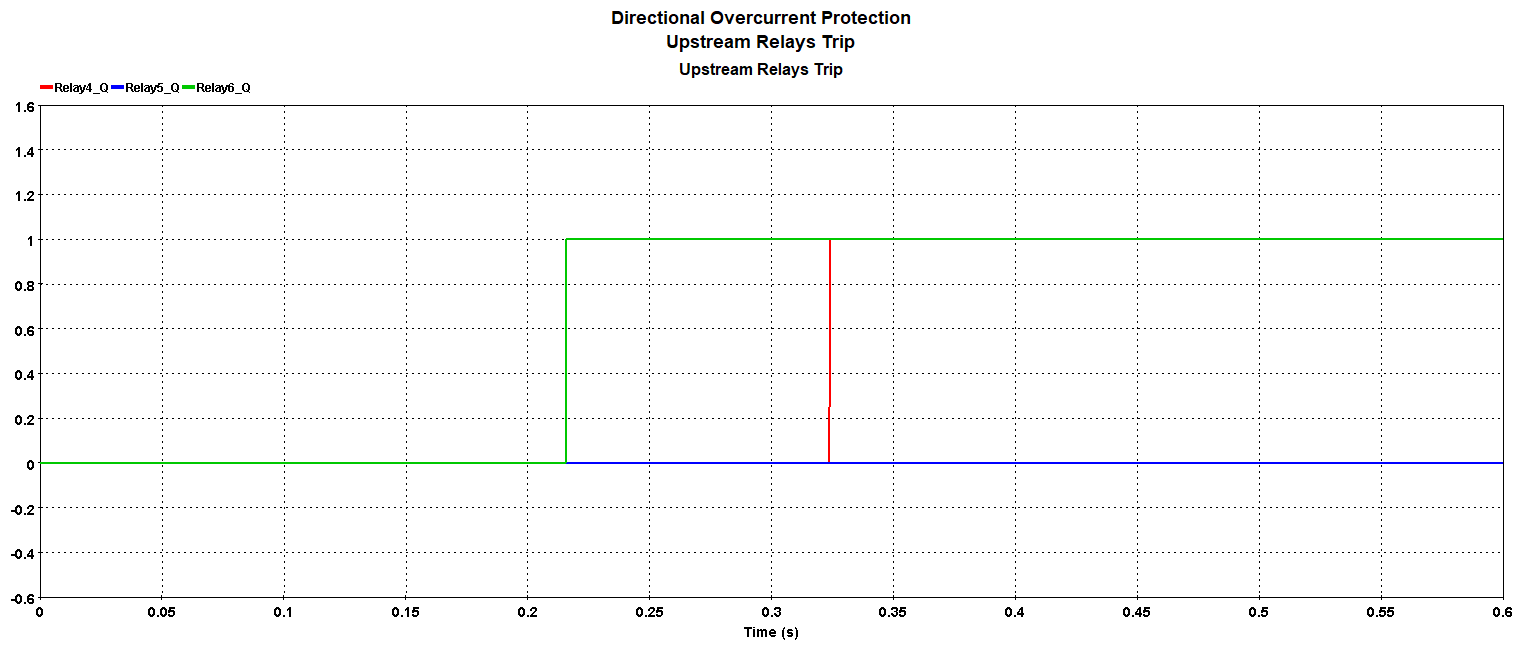

In upstream, relay 6 with the lowest Time Dial setting ( 0.04 s) will pick up first and isolate sections 2 and 3. The DG will still feed the fault as the fault is in section 3 so then relay 4 will pick up and clear the fault. The figure below shows the upstream relays voltages, currents, and the trip outputs.

It can be seen from the figure below that relay 6 (non-directional now) picks up in 0.0158 s (from the time of fault) and opens breaker 6. After CB 6 opens, the DG is still feeding the fault therefore relay 4 picks up in 0.1236 s (from the time of fault) and opens breaker 4 and clears the fault.

Note : It can be seen that even if relay 6 picked up in 0.0158 s (from the time of fault), relay 3 still observes the fault currents because of the breaker operation time delay. Relay 3 picks up in 0.0161 s (from the time of fault).

This shows that in the absence of directional elements the relays fail to discriminate between the healthy and faulty sections. This clearly demonstrates the importance of the directional element which provides selectivity to the Overcurrent relay.

OPAL-RT TECHNOLOGIES, Inc. | 1751, rue Richardson, bureau 1060 | Montréal, Québec Canada H3K 1G6 | opal-rt.com | +1 514-935-2323

Follow OPAL-RT: LinkedIn | Facebook | YouTube | X/Twitter